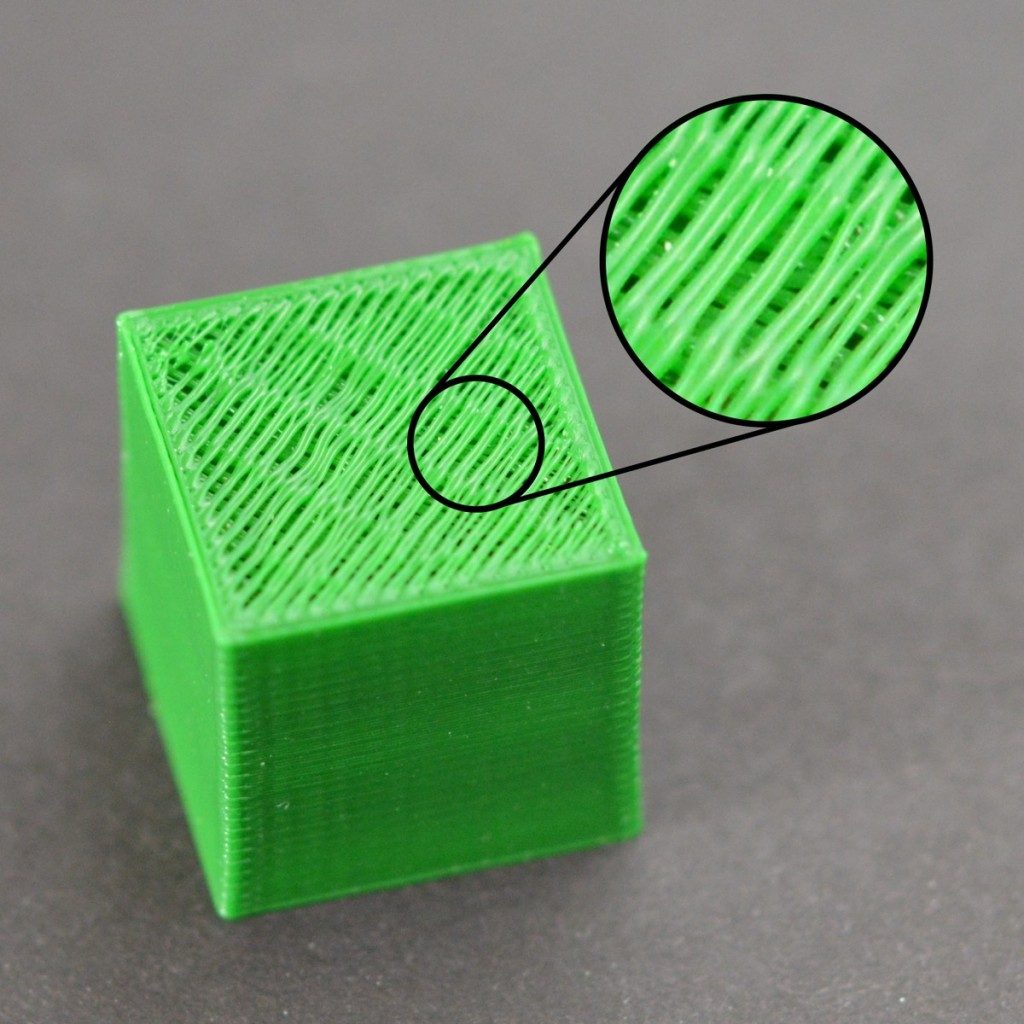

Keep in mind that even my 0.3mm nozzle suffers if the filament changes in diameter too much, so for 1.2mm you need filament that is very constant in diameter over a long distance. Although some 3D CAD applications may include a module to convert models to NURBS, this sideline. If not good at all it means your general extrusion multiplier needs further adjustment. If all good your parts should come out fine now. Watch the layers forming closely and pay attention to any build up that might happen! (You might need to print 2 at a time to allow for enough cooling of the part(s) ) Now print a test cube with 100% infill and 3 perimeters. Lower print speeds help here to find this sweet spot for the infill extrusion. Increase the "infill extrusion width" until the infill lines start to overlap - if they start to form pushed up lines between the extrusion lines you need to lower the width until you get a really smooth surface. They are supposed to be adjusted and saved to give you a reliable outcome once all is working, thei way of explaining it makes you think you push some buttons and get perfect prints right awayĪdjust the "outline overlap" until the turns of your infill really overlap about 30% with the perimeter. As an example, if you were previously using an outline overlap of 20, try increasing that value to 30 to see if the gaps between your perimeters and infill disappear. Only the top layer is calculated a bit different to produce a closed finnish.Īlso these automatic settings or pre-sets are just a baseline. This overlap helps to ensure a strong bond between the two sections.

S3D tries to calculate paths so the extruded filament is just touching on straight lines. I did not go below my 0.3mm but one day I will for sure, so maybe my experience with the 0.3 can help a bit. What works fine in Slic3r usually causes massive over extrusion in S3D - this makes comparing and fixing often quite hard. S3D is quite funny when it comes to "perfect" print settings. But when there is a solid layer in green between the outline and infill overlap does not happen between the. It then says to 'ensures infill bonds to outline'. It says outline overlap not 'infill' overlap. To connect with Simplif圓D, join Facebook today. The attached image has an outline overlap of 50 just to point out the problem and viewing one layer. Was about to say your layers look quite thick until I read your posting again and realised you reall talk about 1.2mm. infill and the perimeters try increasing the Outline Overlap percentage (found in the Infill Tab). Extrusion Width: Constant width of each extruded line within your print. I don't remember what I started with but it was low. My settings are first layer height 100 first layer width 100 first layer speed 50 If you need the lines to go farther out into the perimeter then look at the infill tab and adjust outline overlap. Choose a layer height between 1 mm and 0.5 mm with a 1 mm nozzle, and 0.5 mm to 0.2 mm with a 0.5 mm nozzle. I haven't tried it yet but I assume that anything less than 100 and the lines would overlap. Welcome to the club of people wanting fine details! Some important concepts that you have to know before starting to edit your process settings: Layer Height: The resolution of your print.

0 kommentar(er)

0 kommentar(er)